ID Grinding Solutions: Enhancing Precision with Bay Union Technology

2024-03-28Mould & Die From:Bay Union

In the precision-driven world of manufacturing, Internal Diameter (ID) grinding emerges as a critical process for achieving the exactness and finish required for high-performance components. This specialized grinding operation, which focuses on the interior surfaces of cylindrical parts, demands not only skill and attention to detail but also the right technology and tools.

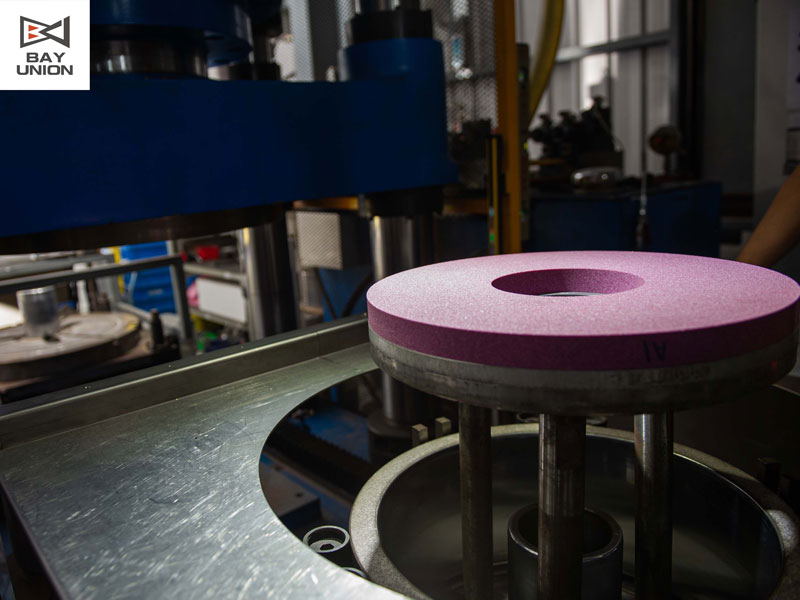

Bay Union Abrasive Technology Co., Ltd. emerges as a leader in this arena, offering state-of-the-art ID grinding wheels that cater to the nuanced needs of precision grinding. Our solutions are specifically designed to tackle the challenges associated with grinding hard and brittle steels, where traditional lathe processing falls short, especially in the creation of taper holes, deep holes, or blind holes.

What Is ID Grinding?

ID grinding is a precise operation designed to finish the internal surfaces of a material, ensuring tight tolerances and superior surface finishes are achieved. This process is essential for manufacturing parts that fit into each other with exact precision, such as gears, bushings, and hydraulic components. The technique involves a grinding wheel that is inserted into the workpiece and moved in a rotational manner to remove material from the inside diameter, making it perfect for creating precise cylindrical cavities.

The Challenge of Internal ID Grinding

ID grinding is vital for manufacturing parts requiring exact internal measurements and high-quality surface finishes. This process becomes indispensable when dealing with materials that defy conventional machining methods due to their hardness and brittleness. The precision required for creating taper holes, deep holes, or blind holes necessitates advanced grinding techniques, where Bay Union's ID grinding wheels excel. These wheels are engineered to navigate the complexities of small internal spaces efficiently, ensuring optimal stock removal and heat discharge.

Industrial Applications of ID Grinding

The application of ID grinding spans multiple industries, each with its own set of challenges and requirements:

- Aerospace: In the aerospace industry, components must adhere to the highest standards of precision and reliability. ID grinding is used to finish jet engine components, hydraulic systems, and landing gear parts, where even the slightest deviation can have significant implications.

- Automotive: The automotive sector relies on ID grinding for the manufacturing of complex engine components, gearboxes, and transmission systems. These parts require precise internal diameters to ensure smooth operation and longevity.

- Medical Devices: Precision is paramount in the medical field, where ID grinding is utilized to create components for surgical instruments, imaging equipment, and other critical medical devices. The ability to achieve smooth, contamination-free surfaces is crucial for patient safety and device efficacy.

- Electronics: As electronic devices become increasingly compact and complex, ID grinding plays a vital role in the production of components with precise internal geometries, ensuring functionality and reliability.

Bay Union's ID Grinding Wheels: Precision Engineered

Bay Union's ID grinding wheels stand at the forefront of abrasive technology, designed to meet the exacting standards of precision and efficiency in ID grinding tasks. Developed with a deep understanding of material removal and thermal dynamics, these wheels facilitate precise material removal and minimize heat generation, ensuring superior surface finishes and dimensional accuracy.

Bay Union: A Partner in Precision

Bay Union Abrasive Technology Co., Ltd. is more than just a supplier of abrasive products; we are a strategic partner in precision manufacturing. Our team of experts provides comprehensive support, from product selection to process optimization, ensuring that our clients achieve the best possible results from their ID grinding operations. With Bay Union, manufacturers gain access to a wealth of knowledge and a suite of innovative products designed to tackle the most challenging ID grinding projects.

Conclusion

In the demanding arena of modern manufacturing, ID grinding stands as a pivotal process for achieving high-precision components. Bay Union Abrasive Technology Co., Ltd. plays a central role in this essential task, delivering advanced ID grinding wheels that meet stringent requirements for precision and surface quality. Our blend of innovative technology and dedicated support equips industries to tackle today's manufacturing challenges, ensuring excellence across every component produced. As we continue to drive forward with our commitment to innovation, quality, and sustainability, Bay Union cements its position as a key partner in the manufacturing sector, helping to advance industries and improve product quality worldwide. In essence, Bay Union is not just providing tools; we're shaping the future of precision manufacturing.

If you're looking to elevate your manufacturing capabilities with precision and efficiency, we encourage you to reach out. Visit our website or contact us to learn more about Bay Union's ID grinding solutions and how they can benefit your operations. Let's work together to achieve the high standards your projects demand.