Future of the Micro Injection Molding in Taiwan

2024-05-02Mould & Die

Introduction:

In the intricate world of precision manufacturing, the micro injection molding industry in Taiwan has carved out a niche of excellence and innovation. Nestled in this evolving landscape is MING-LI PRECISION STEEL MOLDS CO., LTD., a company that has been a driving force in the industry’s transformation. This article explores the journey of micro injection molding in Taiwan, spotlighting the technological advancements and MING-LI’s pivotal role in shaping its future.

Historical Overview:

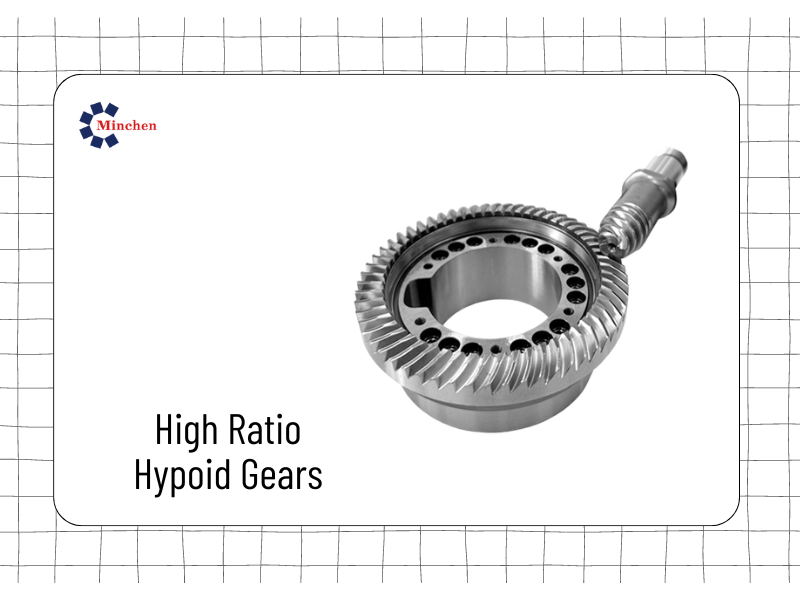

Micro injection molding in Taiwan began its journey in the 1980s, primarily focused on producing small mechanical and optical parts. This era marked the inception of a niche technique that would eventually revolutionize precision manufacturing. In these early days, the industry faced challenges in terms of technology limitations and application scope.

Technological Advancements:

As the years progressed, significant technological advancements played a crucial role in the industry’s evolution. The 1990s and early 2000s witnessed a surge in innovation, with the introduction of high-precision machinery and diverse material options. MING-LI, adapting swiftly to these changes, incorporated advanced technologies to enhance its production capabilities. This period saw the industry transitioning from niche applications to more complex and varied uses.

Rise of Biodegradable Materials:

With the global shift towards sustainability, the micro injection molding industry began exploring biodegradable materials. MING-LI recognized the potential of these materials early on and started incorporating biopolymers like PLA and PHA into its production processes. This move not only aligned with environmental goals but also opened new markets and applications for the company.

Growth in Global Demand for Micro Injection Molding:

Recent market analyses have shown a remarkable upward trajectory in the global demand for micro injection molding. According to a comprehensive study, the micro injection molding market is projected to grow from $904.3 million in 2020 to an impressive $1.6 billion by 2025, marking a compound annual growth rate of 11.8% during this period. This growth is indicative of the expanding application of micro injection molding across various industries, including medical and healthcare, automotive, telecom fiber optics, and micro drive systems and controls.

Regions like North America, the Asia-Pacific, and Europe are experiencing significant growth, underscoring the global reach and applicability of this technology. Key factors driving this growth include the increasing demand for precision parts in the automotive industry and a rise in the number of minimally invasive surgeries, which often require micro-molded components.

Such robust growth in the micro injection molding market not only demonstrates its versatility and efficiency but also underscores the importance of companies like MING-LI staying at the forefront of technology and market trends to maintain a competitive edge in this rapidly evolving field.

Integration of Additive Manufacturing:

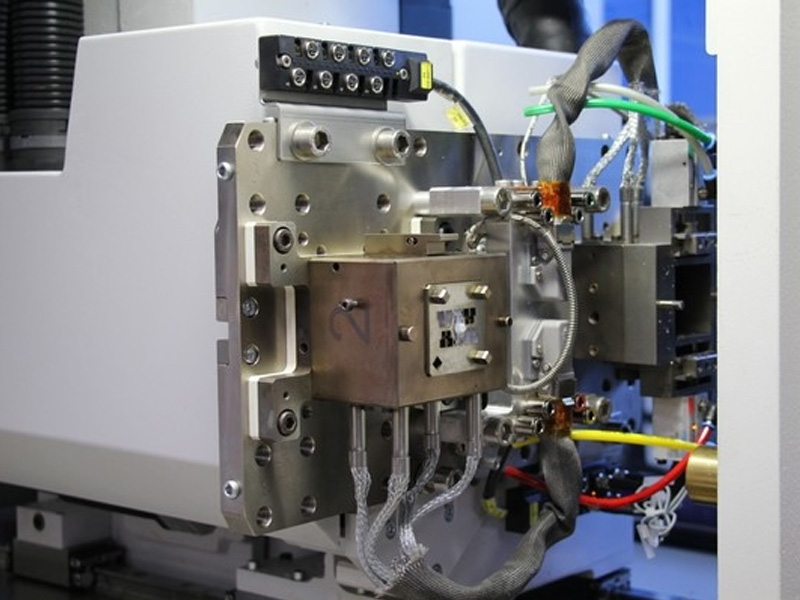

The integration of additive manufacturing marks a significant leap forward. The synergy between 3D printing and traditional micro molding processes has enabled the creation of even more intricate designs. MING-LI’s adoption of this technology has fortified its position as an industry innovator, offering bespoke solutions that defy traditional manufacturing limits.

Automation and AI:

The infusion of robotics and artificial intelligence into micro injection molding has ushered in an era marked by heightened efficiency and precision. MING-LI’s embrace of these cutting-edge technologies has automated key production processes, enhancing product quality and optimizing production timelines, thereby solidifying its leadership in the industry.

MING-LI’s Sustainable Practices:

MING-LI’s commitment to sustainability extended beyond the use of biodegradable materials. The company implemented energy-efficient practices and waste reduction strategies, contributing to a more sustainable manufacturing process. These practices not only reduced the environmental impact but also resonated with the growing eco-consciousness among customers.

The Future of Micro Injection Molding:

As we look towards the future, the micro injection molding industry in Taiwan, led by companies like MING-LI, is poised for further growth and innovation. Emerging trends suggest a continued focus on sustainability, precision, and technological integration.

MING-LI's Vision:

At the heart of MING-LI's future strategy lies a relentless pursuit of innovation and adaptability. The company is geared to remain a step ahead of industry trends, focusing on technological advancements, sustainable practices, and customer-centric solutions. With its rich legacy and progressive outlook, MING-LI is set to continue as a vanguard in the micro injection molding industry.

Conclusion:

The journey of micro injection molding in Taiwan is a testament to the relentless pursuit of innovation and excellence. MING-LI, as a key player in this journey, has not only adapted to changes but has often been a catalyst for them. As the industry evolves, MING-LI’s commitment to quality, innovation, and sustainability ensures that it remains at the forefront of this dynamic field.